The production technology of is advanced, which is in line with the industry standards.

Hydraulic Motor OMP/BMP Series Description

The BM1/ BMP/OMP series hydraulic orbital motor produced by ChangJia is a small volume, economic type axial flow hydraulic motor.

Due to its small size, compact structure, high efficiency, and economical reliability,the BM1/BMP/OMP series orbital hydraulic motors are widely applied in agriculture machinery, plastic industry, mining,fishing machinery, and construction machinery, especially fitted to lower load applications, such as plastic injection mold machine, cleaner, grass cutter,Winches,Conveyors,Slews,Sweeper Drives,Augers,Cutters,Mowers and Chippers.

Ordering Information

Product NO | Displacement(CCM) | Mounting Flange(MM) | Shaft(MM) | Port Size | Drain Port | Shaft end thread | Mounting holes | Oil Port shape | Parallel key width(MM) |

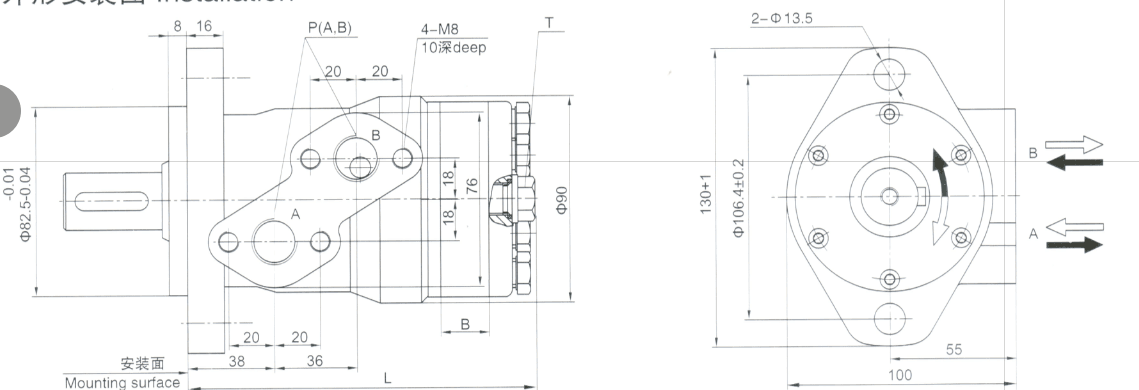

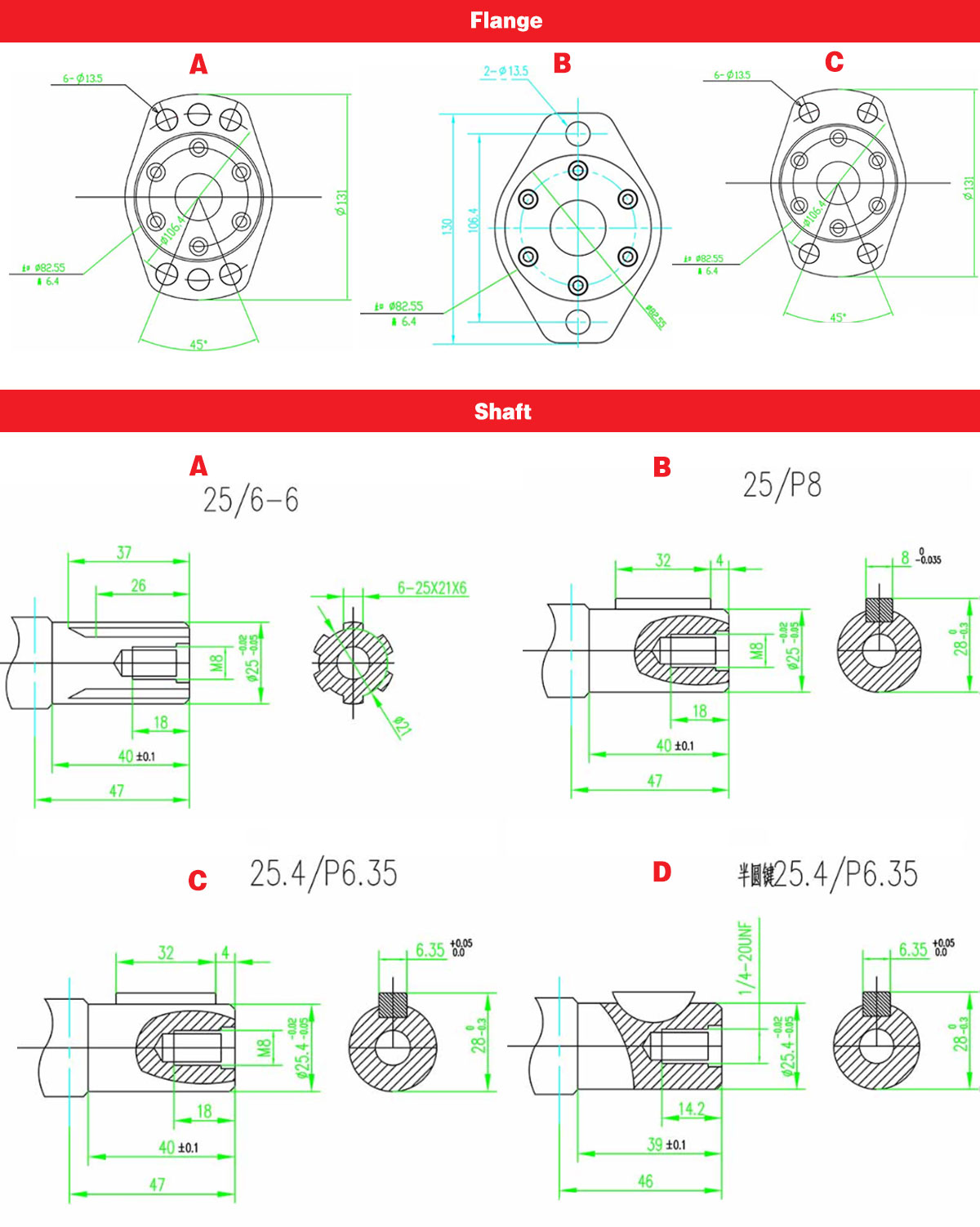

BM1/BMP/OMP | 50-400 | 82.5 | 25 | G1/2 | G1/4 | M8 | 2 | S | 8 |

Characteristic Features

1.Double needle bearing can bear higher radial force,with more Concentricity that can help smooth running under the high speed condition;

2.High quality oil seal lead to longer service life;

3.Shaft seal can bear high pressure of back and the motot can be used in parallel or in series;

4.Special design in the driver-linker and prolong operating life;

5.Special design for distribution system can meet the requirement of low noise of unit;

6.Integration of efficiency and economy to environment-friendly;

7.Compact volume and easy installation;

Main Specification

TYPE | BM1 | BM1 | BM1 | BM1 | BM1 | BM1 | BM1 | BM1 | BM1 | BM1 | |

OMP | OMP | OMP | OMP | OMP | OMP | OMP | OMP | OMP | OMP | ||

Displacement(ml/r) | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 250 | 315 | 400 | |

Flow (LPM) | Continuous | 45 | 45 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

Intermittent | 50 | 50 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | |

Speed (RPM) | Continuous | 879 | 720 | 740 | 589 | 475 | 370 | 296 | 237 | 189 | 149 |

Intermittent | 975 | 755 | 827 | 673 | 594 | 463 | 370 | 297 | 236 | 185 | |

Pressure (MPA) | Continuous | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 11 | 11 | 11 | 10 |

Intermittent | 16.5 | 16.5 | 16.5 | 16.5 | 16.5 | 16.5 | 16.5 | 14 | 12.5 | 10.5 | |

Torque (N*.m) | Continuous | 81 | 101 | 129 | 161 | 202 | 245 | 286 | 360 | 406 | 435 |

Intermittent | 108 | 134 | 171 | 213 | 268 | 342 | 390 | 456 | 505 | 533 | |

1. Continuous pressure:Max.value of operating motor continuously. 2.Intermittent pressure:Max.value of operating motor in 6 seconds per minute . 3.Peak pressure:Max.value of operating motor in 0.6 second per minute. 4.The optimum operating situation should be at the 1/3-2/3 of the continuous operating situation. | |||||||||||

Replace DANFOSS

| 151-0300 | 151-0313 | 151-0607 | 151-0631 | 151-5194 | 151-5217 |

| 151-0301 | 151-0314 | 151-0608 | 151-0632 | 151-5195 | 151-5218 |

| 151-0302 | 151-0315 | 151-0610 | 151-0633 | 151-5196 | 151-5219 |

| 151-0303 | 151-0316 | 151-0611 | 151-0634 | 151-5197 | 151-5221 |

| 151-0304 | 151-0317 | 151-0612 | 151-0635 | 151-5198 | 151-5222 |

Replace EATON/CHAR-LYNN

| 101-1001 | 101-1023 | 101-1045 | 101-1067 | 101-1089 | 101-1352 | 101-1758 |

| 101-1002 | 101-1024 | 101-1046 | 101-1068 | 101-1090 | 101-1449 | 101-1759 |

| 101-1003 | 101-1025 | 101-1047 | 101-1069 | 101-1091 | 101-1459 | 101-1762 |

| 101-1004 | 101-1026 | 101-1048 | 101-1070 | 101-1092 | 101-1463 | 101-1765 |

| 101-1005 | 101-1027 | 101-1049 | 101-1071 | 101-1093 | 101-1466 | 101-1766 |

Replace M+S HYDRAULIC

| MP50 | MP80 | MP100 | MP125 | MP160 | MP200 | MP250 | MP315 | MP400 |

| MLHP50 | MLHP80 | MLHP100 | MLHP25 | MLHP60 | MLHP200 | MLHP250 | MLHP315 | MLHP400 |

Replaceable Orbital Motors Cross Reference Table

CJ | DANFOSS | M+S | EATON | ROSS | WHITE | PARKER | SAM | BOSCH |

HYDRAULIC | HYDRAULIC | CHAR LYNN | TRW | CROSS | BREVINI | RECROTH | ||

BMM | OMM | MM MLHK | J SERIES | BGM | MGX | |||

BM1/BMP | OMP DH | MP HP | H SERIES | MF MG | WP RS | TC TE TB | BG | MGP GXP |

BM2/BMR | OMR DS OMEW | MR HR MLHRW,RW | S,T SERIES W SERIES | MB | WR RE | TF | BR | MGR GMR |

BM4/BMH | OMH | MH MLHH HW HWF | ME | RE | TG | |||

BM5/BMS | OMS | MS MSY MLHS | 2000 SERIES | ME | RE | TG | HPR | MGS GMS |

BM6/BMT | OMT TMT | MT MLHT MTM | 6000 SERIES | MJ | HT | MGT,GMT | ||

BMV | OMV | MV MLHV | 10000 SERIES | MGV GMV |

Usage Guide

1.BM Series motors are designed as low speed high torque and low weight type motors.

2.A simultaneous max,speed and max.pressure is not recommended.

3.Can be used in parallel or in series.Case drain line is necessary when back pressure is over 5 Mpa.

4.The optimum operating situation should be at the 1/3-2/3 of the continuous operating situation.

5.Make sure the motor is always filled with oil before operating.

6.Max.operating temperature:80℃.

7.Recommended fluid:Anti-wear type of hydraulic oil.Viscosity recommended 37-73cst.Filtration:ISO19/16.

Notes:

The products you buy from us with 12 months quality warrenty,during the guarantee period we will replace products free of charge or refund your money in full.

The raw material made for is exported abroad.