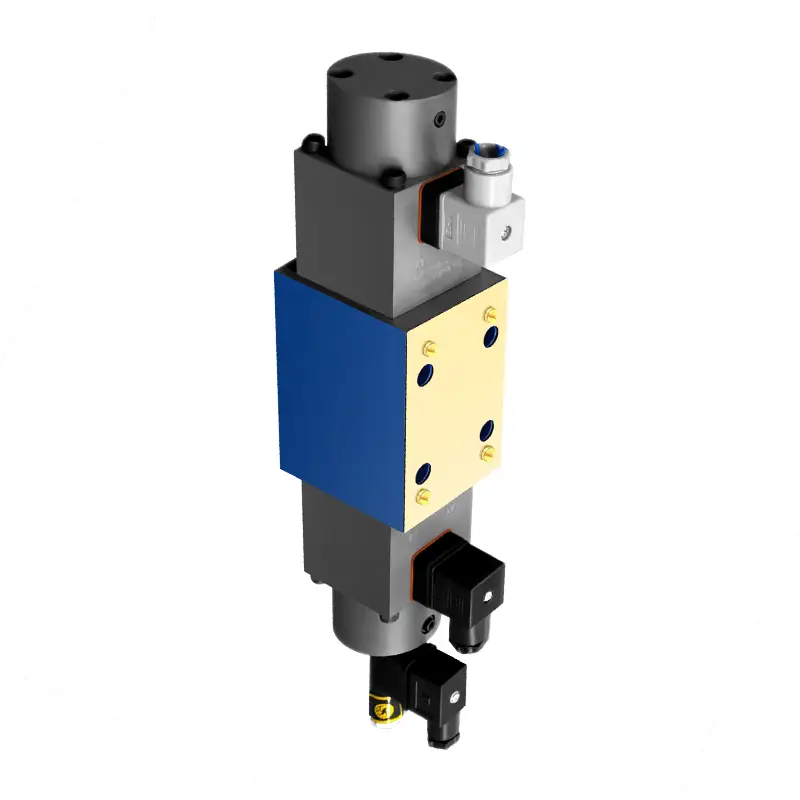

4WRE Type proportional directional valves directactuated without electrical feedback

- For subplate mounting

- Electrical position feedback

- Spring centred control spool

- Low pressure drop across the control lands

- Both valve and electronic control from onesupplier

- Mounting pattern to DlN 24 340 fomm A,ISO4401 and CETOP-RP121H

Product features

◉ Valve for controlling both direction and flow of a hydraulic fluid

◉ For subplate mounting

◉ Electrical position feedback

◉ Spring centred control spool

◉ Low pressure drop across the control lands

◉ Both valve and electronic control from onesupplier

◉ Mounting pattern to DlN 24 340 fomm A,ISO4401 and CETOP-RP121H

Functional section

Type 4WRE directional valves are direct operated by means of proportional solenoids and are used to control the direction and volume of a flow.

They consist basically of housing (1), control spool (4), two return springs (5), two proporional solenoids (2) and a positional transducer (3).

Type 4WRE5 10 ···10B/···(3-position)

lf the solenoid "a" (2) is energised,the spool is moved to the right, the travel being proportional to the electrical input signal.The control spool (4) causes the V-shaped grooves to open progressively to flow.The position of the control spool (4) is monitored by the positional transducer (3). In the electronic control the actual position of the control spool is compared with the pre-set value. Here we have a position control circuit which recognizes existing differences between the pre-set value (command value) and the feedback value (actual value) and corrected by appropriate signals on the relevant solenoids.Once solenoid "a" (2) is de-energised the control spool is returned to its centre position by the return springs (5).

Technical data

(For application outside these parameters, Please consult us!)

|

Hydraulic |

|||

|

Sizo |

6 |

10 |

|

|

Max.fow (Lmin) |

65 |

260 |

|

|

Operabing pressure |

PortABP |

31.5 |

31.5 |

|

Port T |

16 |

16 |

|

|

Hystoress (%) |

<1 |

<1 |

|

|

Roepeatablty (%) |

<1 |

<1 |

|

|

Respons0 sensitvty (%) |

<0.5 ofnominal signal |

<0.5 of nominal signal |

|

|

Frequency esponse (3dB) 0+z) |

6 |

4 |

|

|

Hydraulie fuid |

Mneral ol(for NBR ses).Phosphate ostor(fo FPMseal) |

||

|

Vscosty range (mr²s) |

2.8t 380 |

||

|

Hydraulic fuid tomperature range (C) |

-20t+70 |

||

|

Dogree of contarihation (μm) |

≤20krocommcond 10) |

||

|

Mounling postion |

Optional |

||

|

Weght |

Valve wth 1scienoid |

1.91 |

5.65 |

|

Valve wm 2 solenoids |

2.86 |

7.65 |

|

|

Electrical |

|||

|

Type of voltage |

Diet voltage 24V or 12V |

||

|

Max.ozrrent per solonod (A) |

1.5 |

1.5 |

|

|

col rosstance |

Cold vao at 20℃ |

5.4 |

10 |

|

Max warm vaue |

8.1 |

15 |

|

|

Duty |

Cortinuou |

||

|

Col toemporature (c) |

+150 |

||

|

Enwronment temperature (C) |

+50 |

||

|

Valve insulbation |

IP65 |

||

|

Assocised ampifer |

with 2ramp fimes |

VT-5001820(or2-postions) |

VT-5002520for 2-posions) |

|

wth 1 amo tme |

VT5005S10(for 3positons) |

VT5006510(for 3-postions) |

|

|

Inducive posibonal transducer |

|||

|

Eectrical mesuring system |

LVDT |

||

|

Controlstoko mm) |

±4.5 linear |

||

|

Uineaity tolorance (%) |

1 |

||

|

Col rostanco(Ω) |

I R20 |

56 |

|

|

II R20 |

56 |

||

|

III R20 |

112 |

||

|

Inductviy (mH) |

6t08 |

||

|

Osilator frequency (K0Hz) |

2.5 |

||

|

Valvwe insulbtion |

IP65 |

||

Transient functions with stepped electrical input signals

Contact us