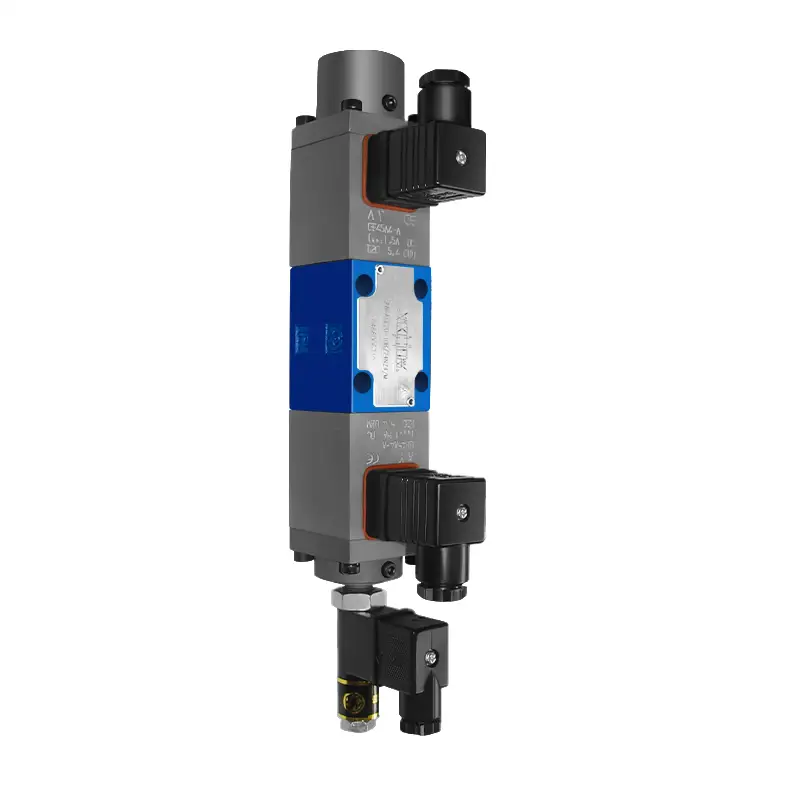

4WRA6 Type proportional directional valves direct actuated without electrical feedback

- For subplate mounting

- For the open loop control of both direction and flow of a hydraulic fluid

- Spring centred control spool

- Low pressure drop across the control lands

- Both valve and electronic control from one supplier

Product features

◉ Direct actuated proportional valve for controlling the direction and volume flow of a hydraulic fuid

◉ For subplate mounting

◉ For the open loop control of both direction and flow of a hydraulic fluid

◉ Spring centred control spool

◉ Low pressure drop across the control lands

◉ Both valve and electronic control from one supplier

Functional section

Type 4WRA directional control valves are direct-operated via proportional solenoids and are used to control the direction and quantity of a flow.

They consist basically of the housing (1), the control spool (3),one or two retum springs (2),and in addition one or two proportional solenoids (5)

Type 4WRA6 10 ...10B/..... (3-position valve)

lf the solenoids are not activated the control spool (3) is maintained in the neutral position by means of the relurn springs (2). Actuation of the control spool (3) is directly via the proportional solenoid (5). if, for instance, solenoid "A" is energised, it will push the control spool (3) to the right in proportion to the electrical signal. Connections are then made from P to B and A to T.

In this way, the control spool(3)causes the V-shaped grooves to open progressively to flow. When the propotional solenoid (5) is de-energised,the control spool(3) is returned to the center position by the return spring(2).

2-position valve

The function of this valve is the same as that for valve type 4WRA. But it's 2-position directional valve with only one proportional solenoid.

Type 4WRA adopts subplate mounting, spring center and low pressure drop acrossing the control lands. They often used in machine light industry, metallurgy, mine, space flight and other fields.

Technical data

(For application outside these parameters, Please consult us!)

| Hydraulic data | |||

|

Size |

6 |

10 |

|

|

Operating pressure(MPa) |

port A,B,P |

31.5 |

31.5 |

|

port A,B,P |

16 |

16 |

|

|

Flow(L/min) |

43 |

95 |

|

|

Degree of contamination |

<20(recommend <10) |

||

|

Hysteresis(%) |

<6 |

<5 |

|

|

Repeatability(%) |

<3 |

<2 |

|

|

Frequency response(-3dB,signal = 100%)(Hz) |

6 |

4 |

|

|

Pressure fluid |

Mineral oil(for NBR seal)/Phosphate ester(for FPM seal) |

||

|

Viscosity range(mm²/s) |

3.8 to 380 |

||

|

Pressure fluid temperature range(°C) |

-30 to +80 |

||

|

Weight(Kg) |

Valve with one solenoid |

1.75 |

5.9 |

|

Valve with two solenoids |

2.5 |

7.5 |

|

| Electrical data | |||

|

Size |

6 |

10 |

|

|

Voltage type |

Direct voltage |

Direct voltage |

|

|

Nominal voltage(V) |

24 |

||

|

Max. current per solenoid(A) |

1.5 |

||

|

Solenoid coil resistance(Ω) |

Cold value at 20°C |

5.4 |

10 |

|

Max. warm value |

8.1 |

15 |

|

|

Environment temperature(°C) |

up to +50 |

||

|

Coil temperature(°C) |

up to +150 |

||

|

Insulation of valve to DIN 40 050 |

IP65 |

||

|

Associated amplifier (24 V rectifier of bridge type) |

VT - 3013 S30 |

VT - 3014 S30 |

|

|

VT - 3017 S30 |

VT - 3018 S30 |

||

Characteristic curves

(measured at ν=36 × 10⁻⁶ m²/s t=50°C )

Contact us