**"The Advantages And Disadvantages Of Gear Pumps In Industrial Use"**

When it comes to powering countless industrial processes, gear pumps have long been a trusted choice for their reliability and efficiency. But like any technology, they come with both strengths and limitations that can significantly impact performance depending on the application. In this article, we’ll explore the key advantages that make gear pumps a popular solution in industries ranging from manufacturing to oil and gas, as well as the potential drawbacks that engineers and operators need to consider. Whether you’re evaluating equipment options or simply curious about how gear pumps work, understanding their pros and cons is essential for making informed decisions in the industrial landscape. Read on to discover the critical insights that can help optimize your operations.

- Overview of Gear Pumps and Their Industrial Applications

**Overview of Gear Pumps and Their Industrial Applications**

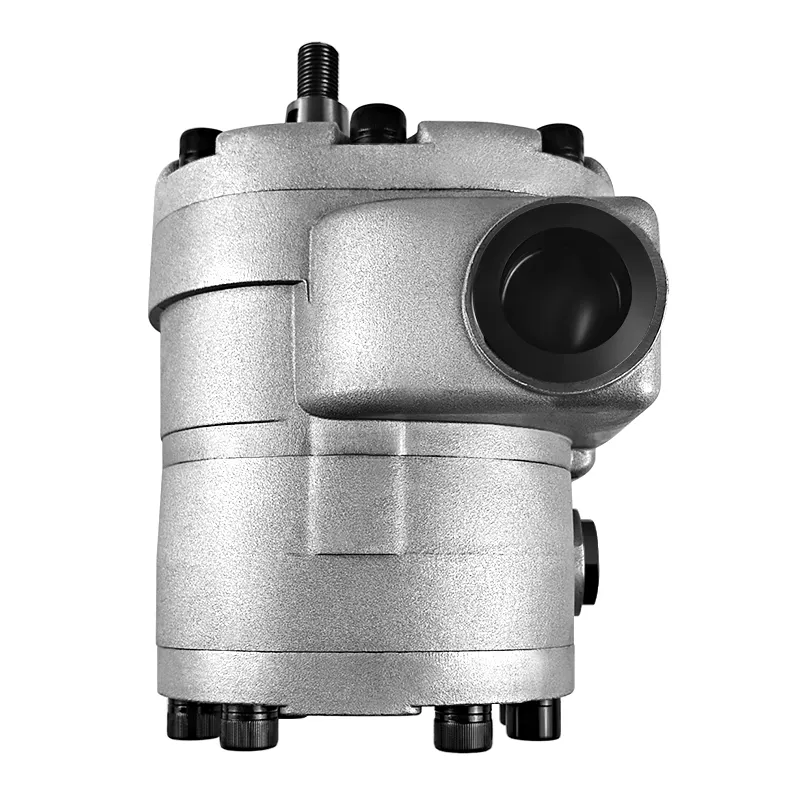

Gear pumps are a type of positive displacement pump widely used across various industries due to their simplicity, reliability, and efficiency in handling a wide range of fluids. Fundamentally, a gear pump operates by using the meshing of gears to pump fluid by displacement. Typically, it consists of two or more gears that revolve inside a closely fitted casing, creating a vacuum at the pump inlet that draws fluid in. The fluid is then transported around the gears and expelled at the pump outlet under pressure. This straightforward mechanism allows gear pumps to deliver a steady, pulse-free flow, making them highly suitable for numerous industrial applications.

The principal components of a gear pump include the driving gear (also called the driver), the driven gear (idler gear), the housing, and inlet and outlet ports. In external gear pumps, the two gears rotate in opposite directions, while in internal gear pumps, a smaller internal gear meshes with a larger external gear, enhancing fluid-handling capabilities under different conditions. The tight clearances between gears and the casing reduce internal leakage, contributing to efficient fluid transfer and consistent pressure delivery. This makes gear pumps an excellent choice for handling viscous and shear-sensitive liquids.

Industrially, gear pumps are favored for their ability to handle a wide range of fluid viscosities, from thin solvents and oils to thick resins and syrups, without significant loss of performance. Their compact size and ability to generate high pressures – often up to several hundred pounds per square inch (PSI) – make them adaptable to both small-scale and large-scale industrial operations. Moreover, their durable construction, often from cast iron, stainless steel, or other corrosion-resistant materials, allows gear pumps to endure harsh environments, aggressive chemicals, and elevated temperatures.

In the chemical industry, gear pumps are commonly employed for metering chemicals, transferring acids, bases, lubricants, and other reactive fluids where precise control over flow rate and minimal pulsation is critical. Their positive displacement nature ensures consistent and repeatable fluid delivery, which is essential for maintaining accurate formulation and process control.

The oil and gas sector relies heavily on gear pumps for moving crude oil, lubricating oils, and hydraulic fluids. Gear pumps’ ability to maintain steady flow under varying pressure conditions makes them ideal for fueling systems and hydraulic circuits. They are also frequently used in fuel injection systems, where precise and reliable fluid delivery directly impacts engine performance and efficiency.

In food processing and pharmaceuticals, gear pumps must meet sanitary standards but are still preferred for transferring viscous liquids like syrups, chocolate, creams, and liquid medicines. Their gentle pumping action helps minimize damage to shear-sensitive ingredients, preserving product integrity. Additionally, modifications such as food-grade coatings and hygienic designs enable their safe use in these sensitive environments.

The automotive industry utilizes gear pumps primarily within lubrication and hydraulic systems. They power the lubrication circuits of engines and transmissions, ensuring effective cooling and friction reduction. Hydraulic power steering, braking systems, and machinery controlling fluid movements commonly incorporate gear pumps because of their reliability and ease of maintenance.

In manufacturing sectors such as plastics and rubber processing, gear pumps regulate the flow of molten polymers and adhesives. Their precision in flow control enables uniform delivery of raw materials into molding and extrusion machines, directly impacting product quality.

Despite their versatility, gear pumps do have operational limits. They are best suited for clean fluids free of abrasive particles to avoid excessive wear on gears and housing surfaces. However, advancements in materials and coatings have expanded the range of fluids gear pumps can handle, including some with particulate content or slight abrasiveness.

Overall, the gear pump is a fundamental component across many industrial applications where consistent fluid transfer, pressure generation, and durability are required. Its blend of mechanical simplicity and robust performance continues to make it the pump of choice across diverse sectors, driving everything from chemical processing lines to automotive systems and food production facilities.

- Key Advantages of Using Gear Pumps in Industrial Settings

**- Key Advantages of Using Gear Pumps in Industrial Settings**

Gear pumps have long been a staple in various industrial applications due to their simple yet highly effective design. Their unique operating principles and adaptable nature make them a favored choice across numerous industries, from chemical processing and food production to automotive manufacturing and hydraulics. When discussing the key advantages of using gear pumps in industrial settings, several factors come into focus, including reliability, efficiency, versatility, and maintenance requirements.

At the core of a gear pump’s appeal is its robust and straightforward design. Typically consisting of two meshed gears—one driven and one idler—gear pumps function by trapping fluid in the cavities between the gear teeth and the pump casing, moving it from the inlet to the outlet side. This mechanical design enables positive displacement, meaning gear pumps deliver a fixed volume of fluid with each rotation regardless of pressure variations. This characteristic provides consistent, pulseless flow, which is critical for many industrial processes requiring precise fluid control.

One of the most significant advantages of gear pumps is their reliability. The use of hardened gears and precision manufacturing ensures that gear pumps can withstand the harsh conditions often found in industrial environments, such as high temperatures, abrasive fluids, and continuous operation. Their rugged construction results in long operational life and minimal downtime, which translates into cost savings for industrial operators. Furthermore, gear pumps are less susceptible to cavitation – a common problem in pumps that can lead to damage and inefficiency – as their design can smoothly handle viscous, heavy oils and fluids with particulates.

Efficiency is another strong point of gear pumps. Due to their positive displacement mechanism, gear pumps maintain a steady output flow and pressure, even when system conditions fluctuate. This consistency makes them ideal for applications that demand precision, such as metering and dosing of chemicals. In addition, gear pumps boast relatively high volumetric efficiency compared to some other pump types. Their close gear tolerances and tight sealing between the gears and housing minimize fluid slippage, ensuring that nearly all of the fluid displaced during each rotation is effectively transferred. As a result, industries benefit from reduced fluid wastage and optimized energy consumption, both vital for operational sustainability.

Versatility broadens the scope where gear pumps can be an excellent choice. Available in various configurations—including external and internal gear pumps—they can handle a wide range of fluids with differing viscosities, from thin solvents to thick oils and grease. Many industrial sectors demand pumps capable of working with unconventional or challenging fluids, and gear pumps typically meet these requirements without sacrificing performance. Customization options, such as different materials for gears and casing (ranging from steel to specialty alloys and plastics), enable gear pumps to resist corrosion and wear based on the specific fluid chemistry involved.

Maintenance-wise, gear pumps present another advantage for industrial users. Their relatively simple mechanical assembly means service and repairs are straightforward and cost-effective. The modular nature of gear pump components allows for easy replacement of individual parts like gears, shafts, and seals without the need for extensive downtime or specialized technicians. This accessibility enhances plant efficiency and keeps production lines running smoothly. Additionally, the steady, low-vibration operation of gear pumps reduces stress on connected piping and systems, contributing to overall longevity and system integrity.

Moreover, the compact size and design aesthetics of gear pumps make them suitable for installations where space is limited. Their compatibility with both horizontal and vertical mounting orientations grants engineers more flexibility when designing equipment layouts. This adaptability is often beneficial in compact industrial plants where optimizing space utilization is critical.

In many industrial applications, safety and environmental considerations are paramount. Gear pumps lend themselves well to these concerns due to their leak-free operation and durability under rigorous conditions. Many models incorporate sealing systems designed to minimize leakage of potentially hazardous fluids, helping companies comply with stringent environmental regulations.

In conclusion, gear pumps in industrial settings bring together a combination of reliability, efficiency, versatility, ease of maintenance, and operational safety. These advantages make gear pumps an indispensable component in numerous manufacturing and processing industries where dependable fluid handling is paramount.

- Common Limitations and Challenges of Gear Pumps

**- Common Limitations and Challenges of Gear Pumps**

Gear pumps have long been a staple in industrial fluid handling due to their simplicity, reliability, and efficient pumping of viscous fluids. However, despite their numerous advantages, gear pumps come with specific limitations and challenges that users must consider when selecting them for various industrial applications. Understanding these constraints is essential to optimize performance, extend the lifespan of the equipment, and avoid operational difficulties.

One of the most significant limitations of gear pumps is their sensitivity to fluid properties, particularly viscosity and particulate content. Gear pumps excel in pumping high-viscosity fluids like oils, resins, and lubricants, but their efficiency may sharply decline when handling low-viscosity liquids such as water or solvents. Since gear pumps operate by trapping fluid between the gear teeth and the casing, low-viscosity fluids can slip back, causing volumetric inefficiency known as internal leakage or slip. This slip not only reduces flow rate accuracy but also increases the pump’s loading, potentially leading to wear or damage over time.

Moreover, gear pumps are typically not designed to handle fluids containing abrasive particles or solids. The tight clearances between the gears and the housing make the gear pump particularly susceptible to damage from suspended particulates. Even small solid contaminants can cause scoring or scratching on the gear teeth and the casing surface, accelerating wear and often resulting in premature failure. In applications where the process fluid is not adequately filtered, the maintenance frequency rises dramatically, causing increased downtime and operational costs.

Another challenge related to gear pumps involves pressure limitations. While gear pumps generally perform well in medium-pressure applications, their operational pressure range is limited by the mechanical strength of the internal components and the sealing arrangements. When subjected to pressures beyond their design limits, gear pumps may develop increased noise, vibration, or even catastrophic failure due to gear tooth fatigue or seal rupture. Consequently, in industries demanding very high-pressure fluid transfer, alternative pump types, such as piston or plunger pumps, may be more suitable.

Thermal sensitivity is another notable challenge with gear pumps. Since the pumps rely on close internal clearances, operating temperature greatly affects pump performance. Excessive heat can cause thermal expansion of components, reducing the clearance between gears and the casing and consequently increasing the risk of seizure or scuffing. Additionally, some industrial fluids pumped via gear pumps may become more viscous as they cool, further stressing pump components or reducing output flow. Efficient cooling and temperature monitoring systems are therefore recommended in applications with fluctuating or high-temperature fluid conditions.

Furthermore, gear pumps are inherently prone to noise and vibration compared to other positive displacement pumps. The meshing of gears generates characteristic noises and vibration levels, which may create operational challenges in noise-sensitive environments or complicate maintenance efforts. Excessive vibration might also indicate underlying issues such as misalignment, wear, or cavitation and could accelerate component failure if left unaddressed.

One more critical challenge arises from the maintenance complexity associated with gear pumps. While gear pumps are relatively simple devices, disassembling them for repair or inspection requires precision, particularly when handling the small, tightly-fitted components. Any slight deviation during reassembly can diminish pump efficiency or cause damages such as gear misalignment or bearing wear. Ensuring proper maintenance expertise and scheduling is vital to minimize unplanned downtime.

Leakage is another limitation to consider. Although gear pumps provide positive displacement and effective fluid transfer, their design inherently allows for some internal leakage, especially under wear conditions. Over time, the buildup of internal clearances creates pathways for fluid to recirculate back to the inlet side, reducing volumetric efficiency and potentially causing heat buildup, which negatively impacts pump longevity.

Lastly, gear pump performance may be adversely influenced by cavitation, a condition where vapor bubbles form due to local pressure drops within the pump. Cavitation can damage gear surfaces and internal components, leading to noise, vibration, and ultimately pump failure. This condition often arises from inadequate suction pressure or fluid vapor pressure being too high for the operating environment, emphasizing the importance of correct installation and operational parameters.

In conclusion, while gear pumps offer numerous advantages in industrial fluid handling, they are not without their limitations and challenges. Issues such as sensitivity to fluid properties, pressure and temperature restrictions, wear by particulates, noise and vibration levels, and maintenance demands must all be carefully evaluated. By understanding these common limitations of gear pumps, industrial users can better select, operate, and maintain these pumps to maximize their effectiveness and lifespan.

- Comparing Gear Pumps with Alternative Pumping Solutions

**- Comparing Gear Pumps with Alternative Pumping Solutions**

In the realm of industrial fluid handling, selecting the appropriate pump is critical to achieving operational efficiency, reliability, and cost-effectiveness. Among the various options available, the gear pump stands out as a common choice for many industrial applications due to its simplicity and durability. However, when evaluating pumping solutions, it is essential to compare gear pumps with alternative technologies such as centrifugal pumps, diaphragm pumps, and piston pumps to determine the best fit for specific needs.

**Fundamental Operating Principles**

Gear pumps operate on a positive displacement mechanism. They use meshing gears to transfer fluid by trapping it between the gear teeth and the pump casing and moving it from the inlet to the outlet. This design contrasts with centrifugal pumps, which rely on the kinetic energy generated by a rotating impeller to move fluid, and diaphragm pumps, which use a reciprocating diaphragm to create suction and discharge pressure.

The positive displacement nature of gear pumps gives them a significant advantage in applications requiring precise and consistent flow rates, regardless of pressure variations. In contrast, centrifugal pumps are flow-variable; their output depends heavily on the system pressure and can fluctuate during operation, making them less suitable for applications demanding exact volumes.

**Viscosity Handling and Fluid Types**

One of the key attributes of gear pumps is their ability to handle highly viscous fluids effectively. Because gear pumps mechanically displace fluid, they can move thick oils, syrups, polymers, and other dense liquids with consistent flow and minimal slip. For example, in industries like lubrication, chemical processing, and food manufacturing, gear pumps are ideal for precise metering and continuous pumping of viscous substances.

In comparison, centrifugal pumps face challenges when dealing with high-viscosity fluids. Their reliance on impeller velocity to generate flow means increased resistance from viscous fluids, reducing efficiency and potentially causing overheating or cavitation. Similarly, diaphragm pumps can handle viscous fluids if designed properly, but they tend to operate at lower flow rates and pressures, which may not suit all industrial processes.

**Pressure and Flow Rate Capabilities**

Gear pumps excel in delivering steady, high-pressure output, often accommodating pressures up to several hundred psi depending on design and materials. This capability makes them suitable for hydraulic systems, lubrication circuits, and fuel transfer where consistent pressure is crucial. Additionally, gear pumps maintain a nearly constant discharge volume per revolution, which is beneficial for batch processing and dosing.

Alternatively, centrifugal pumps generally offer higher flow rates but at lower pressures compared to gear pumps. Their efficiency peaks when operating near their design point, but they may not maintain specific flow or pressure requirements if system conditions fluctuate widely. Piston pumps, another alternative, can handle very high pressures and viscous fluids, but their complexity, cost, and maintenance needs are typically higher than those of gear pumps.

**Durability, Maintenance, and Cost Considerations**

Gear pumps are known for their rugged construction, with fewer moving parts and tight tolerances that facilitate long service life under harsh industrial conditions. Their maintenance involves routine checking of clearances, seals, and bearings, which can often be done without full disassembly. This contrasts with diaphragm pumps, which require diaphragm replacement and can suffer from wear due to diaphragm fatigue, and piston pumps, which involve more complex maintenance due to multiple moving components.

From a cost perspective, gear pumps usually offer a competitive upfront price and low operating costs for many industrial applications. Centrifugal pumps might be cheaper for large-volume, low-pressure scenarios, but their inefficiency with viscous fluids or variable loads can raise long-term costs. Diaphragm and piston pumps, while useful in niche cases (such as handling corrosive or abrasive fluids), tend to have higher initial costs and more intensive maintenance requirements.

**Application Suitability and Industry Preferences**

Each pump type has its ideal application niches. Gear pumps dominate in industries requiring accurate lubrication, heat transfer oil circulation, and fuel injection due to their steady output and viscosity handling. Centrifugal pumps, with their capability to handle large volumes of low-viscosity liquids at varying flow rates, are preferred in water treatment and cooling systems. Diaphragm pumps find their place in chemical dosing where shear-sensitive or hazardous fluids are involved, and piston pumps are chosen for extremely high-pressure applications such as hydraulic presses.

Ultimately, the choice between gear pumps and alternative pumping solutions hinges on the specific industrial parameters: fluid characteristics, required pressure, flow rate, operational consistency, maintenance budgets, and environmental considerations. While gear pumps provide a balanced and reliable solution for many tasks, industries must weigh these factors carefully against the operational profile of other pump technologies to optimize both performance and cost-effectiveness.

- Best Practices for Optimizing Gear Pump Performance in Industry

**Best Practices for Optimizing Gear Pump Performance in Industry**

Gear pumps are widely utilized in industrial applications due to their robust design, steady flow characteristics, and ability to handle a range of fluids. However, to fully harness the capabilities of gear pumps and extend their service life, it is crucial to implement best practices that optimize their performance. This article delves into various strategies and considerations to enhance the efficiency, reliability, and longevity of gear pumps used in industrial settings.

### 1. Proper Selection of Gear Pump Type and Materials

Optimizing gear pump performance begins even before installation, with the careful selection of the appropriate gear pump type and materials based on the application requirements. Gear pumps come in external and internal gear varieties, each suited to different fluid viscosities and operating conditions. For instance, external gear pumps are ideal for handling thicker fluids and providing steady high-pressure output, while internal gear pumps perform well with low-viscosity liquids.

Material compatibility is another critical factor. Using corrosion-resistant materials such as stainless steel or specialized alloys can prevent premature wear and chemical degradation when pumping aggressive or abrasive fluids. Selecting the right gear pump type and materials ensures better pump performance and reduces downtime due to unexpected failures.

### 2. Ensuring Proper Installation and Alignment

Incorrect installation is a common reason gear pumps fail prematurely in industrial environments. Ensuring the pump is properly mounted and aligned with the driving motor or engine is essential to prevent excessive vibration, shaft misalignment, and bearing wear. These mechanical stresses can cause gear teeth damage or seal failure, reducing the pump’s operational efficiency.

To optimize performance, use precision alignment tools during installation and verify the foundation or mounting surface is level and stable. Flexible couplings can help accommodate minor misalignments and reduce transmitted forces, thereby protecting the gear pump from mechanical overload.

### 3. Maintaining Fluid Cleanliness and Using Appropriate Filtration

Gear pumps are sensitive to contamination in the pumped fluid. Abrasive particles and solid contaminants can cause rapid degradation of gears and bearings due to increased friction and wear. Industrial processes commonly involve fluids that vary widely in cleanliness; therefore, implementing effective filtration systems before the fluid enters the pump is paramount.

Regularly replacing or cleaning filters, employing magnetic or cyclone separators, and conducting routine fluid analysis help maintain fluid cleanliness. By preventing contaminants from entering the gear pump, industries can significantly enhance pump reliability and avoid costly repair or replacement.

### 4. Monitoring and Controlling Operating Conditions

Gear pumps exhibit peak performance when operating within the recommended pressure, temperature, and speed limits. Exceeding these parameters can cause gear tooth damage, excessive heat buildup, seal failure, or cavitation.

Installing pressure relief valves, temperature sensors, and flow meters allows real-time monitoring of operating conditions. Automated shutdown mechanisms can protect the gear pump from adverse conditions such as dry running or pressure spikes. Proper control and adjustment of operating parameters help maintain optimal pump efficiency and prevent damage.

### 5. Regular Preventive Maintenance and Lubrication

Preventive maintenance is a key factor in optimizing gear pump performance. Periodic inspection of gear teeth, bearings, seals, and housings helps identify early signs of wear or damage. Timely replacement of worn components prevents catastrophic failure and unplanned downtime.

Lubricating the gears adequately reduces friction and heat generation, prolonging gear pump life. Selecting the appropriate lubricant based on the pumped fluid and operating temperature is critical. Some gear pumps are lubricated by the pumped fluid itself, while others require external lubrication. Following manufacturer recommendations for lubrication intervals and types is essential for maintaining peak performance.

### 6. Managing Fluid Viscosity and Temperature

The viscosity of the fluid has a direct impact on gear pump efficiency. Extremely high viscosities increase power consumption and reduce flow rates, while too low viscosities can lead to internal leakage and inefficiencies. Industrial users should aim to maintain fluid viscosity within the operational range specified for their gear pump.

Additionally, temperature control is vital. Excessive temperatures can degrade both the pump materials and the fluid, affecting performance and longevity. Heat exchangers or cooling systems may be necessary in some industrial processes to maintain optimal fluid temperature, ensuring the gear pump operates efficiently without overheating.

### 7. Implementing Flow Control and Back Pressure Optimization

Gear pumps ideally operate under a steady flow condition, as fluctuations can cause mechanical stress and noise. Using flow control devices such as variable speed drives or throttling valves allows fine-tuning of the pump’s output to meet process demands without overloading the system.

Back pressure plays a role in stabilizing pump operation. Ensuring there is sufficient back pressure prevents gear slippage and ensures consistent fluid delivery. Industrial operators should carefully design piping and process configurations to maintain adequate back pressure and avoid conditions that could lead to cavitation or flow interruptions.

### 8. Training and Operator Awareness

Finally, optimizing gear pump performance requires well-trained operators who understand the pump’s operational principles and maintenance needs. Providing education on startup and shutdown procedures, monitoring techniques, and troubleshooting common problems helps prevent user-induced failures and enhances overall system reliability.

In conclusion, optimizing gear pump performance in industry is multi-faceted, encompassing proper selection, installation, fluid management, operating condition control, preventive maintenance, and operator training. Adhering to these best practices ensures that gear pumps deliver efficient, reliable service over their operational life, maximizing the benefits of this vital industrial component.

Conclusion

In conclusion, gear pumps remain a reliable and widely used solution in various industrial applications due to their robust design, efficiency, and consistent performance. However, as with any technology, they come with certain limitations such as sensitivity to fluid viscosity and potential wear concerns that must be carefully managed. Drawing on our 15 years of industry experience, we understand that selecting the right gear pump requires balancing these advantages and disadvantages alongside specific operational needs. By partnering with a knowledgeable provider, businesses can ensure optimal pump selection and maintenance strategies that maximize productivity and longevity in their industrial processes.

![]() Public Mailbox: info@changjia.com

Public Mailbox: info@changjia.com

Contact us